WHEEL GEAR UNIT

Renovating 136 railway gear units in the city of St. Louis/USA

In the course of implementing preventive maintenance measures at MetroLink St. Louis (Light Rail Vehicle), Eisenbeiss Industrial Gear Service was responsible for maintaining and renovating the wheel unit gear systems.

As a lead-up to the project, comprehensive measurements were made and resulting re-engineering planned for the relevant gear unit type. Defining and procuring the spare parts packages in advance made sure that the necessary components were available at the service centre in Sacramento. The parts involving gear teeth were manufactured at the Eisenbeiss plant in Enns / Austria. Designing special work rigs and tools as well as defining work processes in advance ensures smooth implementation of the maintenance work at our service centre in Sacramento.

Application: wheel unit gears for railway vehicles (Light Rail Vehicle)

Gear manufacturer: Voith

Type: SZ15

Gear type: 2-stage spur gear system

Data for repair: maintenance instruction available; no drawings provided

Damage: bearings and gear teeth worn; individual bearings damaged; damage to shaft seals

Work carried out:

- Sample recording of a complete gear unit

- Re-engineering and improved parts design

- Create gear documentation including drawings and parts list

- Purchase all necessary spare parts (manufacturer gear components at Eisenbeiss headquarters in Enns / Austria)

- Design and manufacture installation tools

- Define work processes for renovating gears

- On-going gear unit renovation work in Sacramento

Turnaround time:

- Total project time for 136 units 2 years

- One set of 4 gear units is completely overhauled within 2 weeks

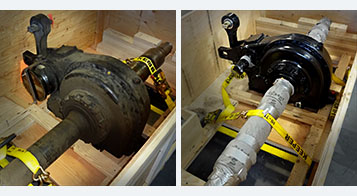

Voith SZ15 wheel unit before and after overhaul

Dismantling Voith SZ15 gear unit

Some bearings damaged

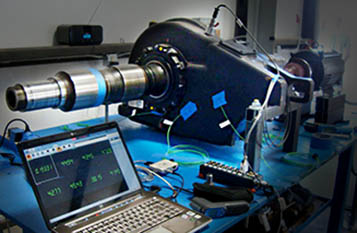

Test run with vibration monitoring

More Examples