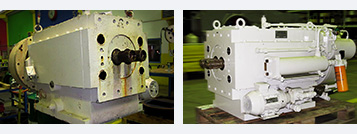

KISSLING – TWIN SCREW EXTRUDER GEAR UNIT

Gear unit repaired after damage to gear teeth

Application: co-rotating twin screw extruder for producing livestock feed

Gear manufacturer: Kissling

Type: EX-101/280

Gear type: co-rotating twin screw extruder gear unit

Data for repair: assembly drawing available

Damage: gear teeth damage on all gear sections

Work carried out:

- Dismantle, check for cracks and assess condition of gear teeth

- Record sample and determine gear tooth data for damaged gear mesh

- Re-engineering (optimisation of gear parts design and improvements to lubrication system)

- Make new gear teeth parts

- Replace all bearings and seals

Turnaround time: 8 weeks

Extruder gear unit before and after overhaul

Worn spline shaft profiles on output shafts

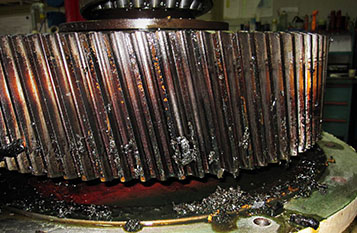

Gear teeth damage on pinion shaft

Severe wear to metal surfaces and damage to teeth on a spur gear

More Examples