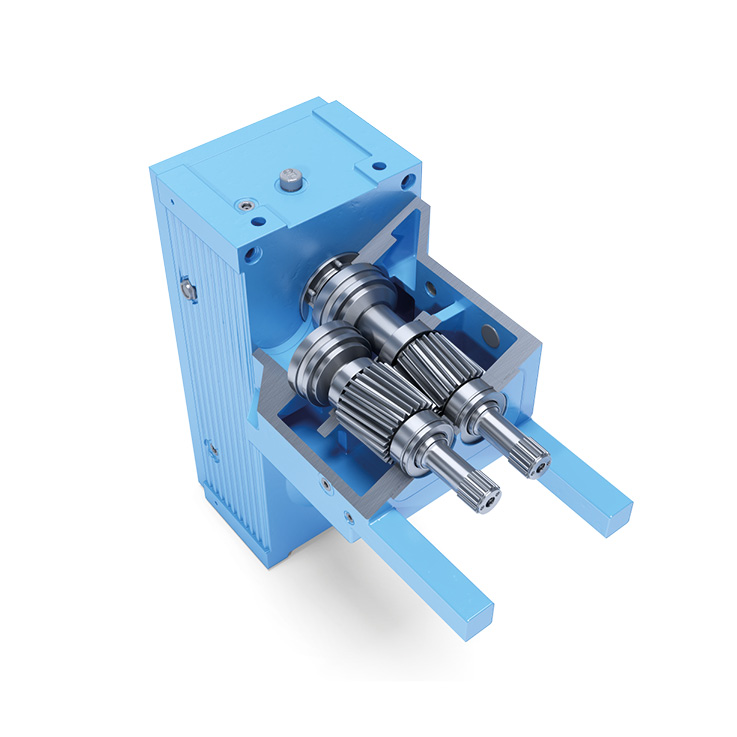

CONICAL COUNTER-ROTATING GEAR SYSTEMS

Conical twin screw extruders are used mainly as co-extruders or as stand-alone machines

for limited outputs.

Manufacturing gear systems for twin-screw conical extruders and the conical gears

needed for them requires highly specialized machinery and exceptional fabrication know-how.

Eisenbeiss is one the few gear system manufacturers worldwide that can fabricate

gear systems for twin-screw conical extruders, rounding off its range of products as

a complete solution supplier of specialised gear systems for extrusion technology.

Eisenbeiss conical counter-rotating gear units are designed precisely to meet

each customer’s specifications.

TECHNICAL DATA

POWER RATING: 11 to 220 kW

OUTPUT TORQUE: 1,000 to 40,000 Nm per shaft

OUTPUT SPEED: 30 to 60 rpm

RATIO: 30 to 90

LUBRICATION / COOLING: splash or forced-feed lubrication with optional oil cooling

SCREW BACK PRESSURE: up to 500 bar continuous load

SCREW DIAMETER: 35 to 125 mm

ADVANTAGES

![]()

![]()

APPLICATIONS

PVC-EXTRUSION

Thanks to consistent specialisation Eisenbeiss have become a dynamic, innovative and internationally leading centre of competence for drive concepts in the field of plastics extrusion. The leading machinery manufacturers in the extrusion branch count on the expertise of our engineers and also our many years of experience in producing special gear systems.