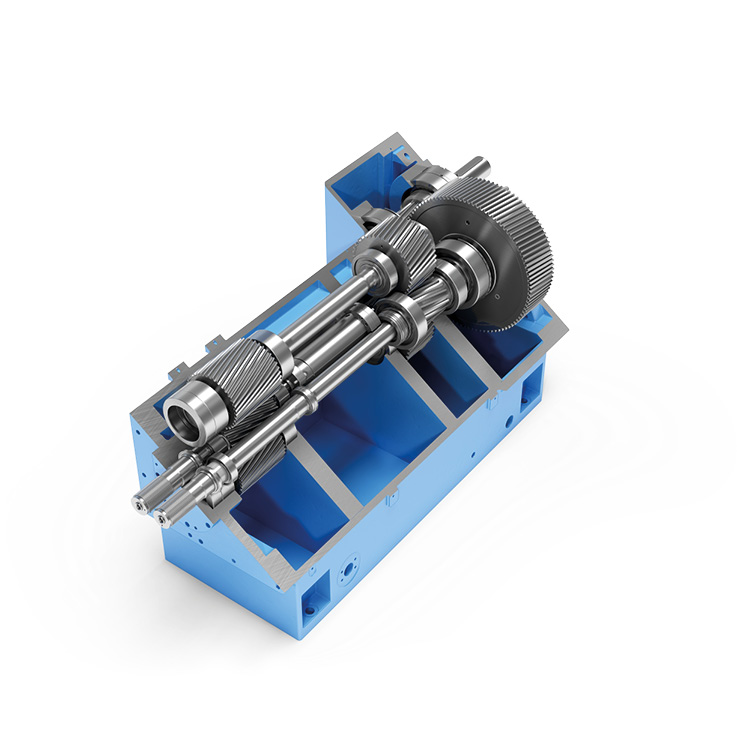

PARALLEL CO-ROTATING GEAR SYSTEMS

In response to the steady trend toward higher and higher outputs from extrusion facilities, which necessarily involves increasing torque, Eisenbeiss has consistently continued to refine its gear systems for parallel co-rotating extruders.

The Speed Star® load distribution system with two distribution shafts has already proved its worth hundreds of times in production around the world has been retained, while the gear system has been upgraded in terms of performance achievable without compromising on reliability. With the latest generation of Speed Star® gear systems Eisenbeiss achieve torque densities up to 20 Nm/cm³ per output shaft.

Eisenbeiss parallel co-rotating gear units are designed precisely to meet each customer’s specifications.

TECHNICAL DATA

POWER RATING: 11 to 5,200 kW

OUTPUT TORQUE: 100 to 55,000 Nm per shaft

OUTPUT SPEED: 600 to 1,800 rpm

RATIO: 1 to 5

LUBRICATION / COOLING: splash or forced-feed lubrication with optional lubrication unit

SCREW BACK PRESSURE: up to 250 bar continuous load

SCREW DIAMETER: 25 to 240 mm

ADVANTAGE

![]()

![]()

APPLICATIONS

COMPOUNDING

Torques of up to 20 Nm/cm³ per shaft are possible at operating speeds of up to 1800 rpm. This provides your customers with a much higher production output. The gear unit consists of a single-piece housing without any joins, completely eliminating potential leaks.

FOOD INDUSTRY

The proven Speed Star® concept is also used in food extrusion. Due to the different power and speed requirements compared to compounding, we have developed our own gear units for this industry sector.