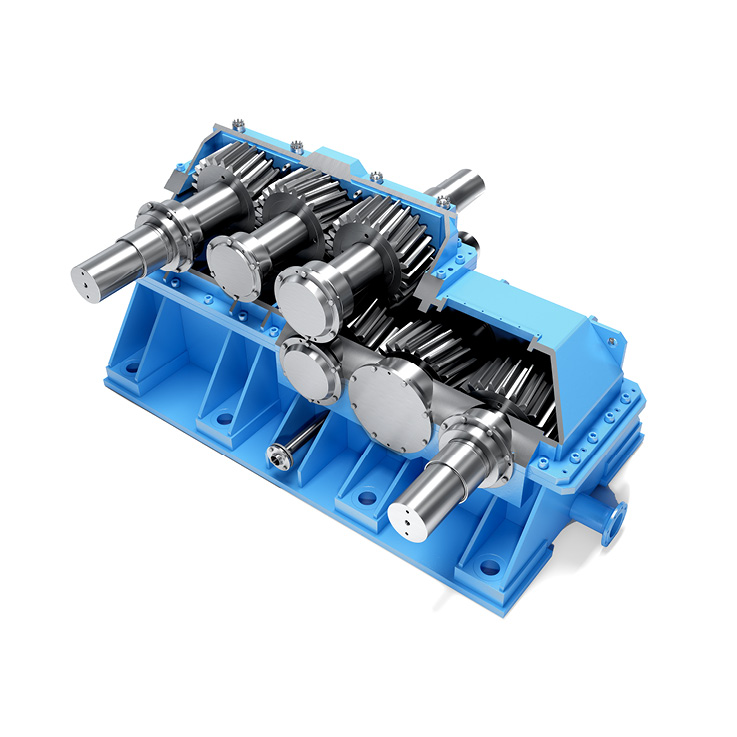

TWIN-DRIVE GEARS

Eisenbeiss twin-drive gears output up to 6 MW divided between two independent drive shafts. Modern calculation methods for gearing and shafts, combined with state-of-the-art processing machines for corrected gearing, enable short work roll gaps.

The high strength of the casing and low-vibration design of the spur gears ensures that strip is rolled flawlessly

TECHNICAL DATA

GEAR TYPE: spur gear systems

POWER RATING: 500 kW to 6,000 kW

OUTPUT SPEED: 25 to 1,000 rpm

RATIO: 1.5 to 20

LUBRICATION / COOLING: forced-feed lubrication / external cooling

POWER RATING: 500 kW to 6,000 kW

OUTPUT SPEED: 25 to 1,000 rpm

RATIO: 1.5 to 20

LUBRICATION / COOLING: forced-feed lubrication / external cooling

ADVANTAGE

![]()

Maximum plate strengths due to closely spaced axles.

APPLICATIONS

ROLLING MILLS

Eisenbeiss has developed special gear systems for cold rolling mills that enable closer axle spacing to achieve small roll diameters. Thanks to the high power density of the gears it is possible to process high tensile steel and aluminium products. The gears are designed for smooth and vibration free operation, which is especially important when processing thin aluminium sheet.