SERVICING

INDUSTRIAL GEAR SYSTEMS

Let us make your old gear system perform like new! We are extremely well equipped to perform the most complex gear repairs to the very highest quality standards.

Reconditioning gear systems like new involves completely dismantling and cleaning the gear unit. We inspect each gearing component using ultrasound and magnetic powder crack detection (as per test certificate EN10204/3.1.B) to ensure that it is undamaged. To make sure there is no deep damage in the gear casing, we measure the casing components precisely and then check them for distortion during operation. Any spare parts required are then manufactured using the state-of-the-art machinery in the Eisenbeiss workshop (we always consult the customer first, before going ahead with manufacturing new parts). All bearings are replaced as standard procedure to comply with the high Eisenbeiss quality criteria.

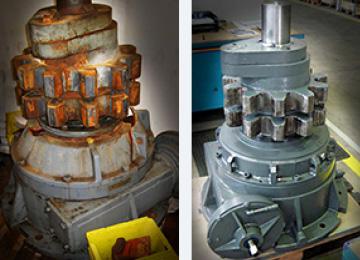

Reconditioning like new a worm drive planetary gear unit (chain tensioning system). Among other things, we repair-welded the fractured middle section of the casing.

Magnetic powder crack detection as per test certificate EN10204/3.1.B

Measuring the teeth geometry on a damaged pinion shaft

Casing measured using modern FARO measurement arm

Component manufacturing in the modern Eisenbeiss workshop: hobbing teeth flanks on spur gears up to a diameter of 1,800 mm

Service & Repair Categories: