GEARCONTROL-SYSTEM

THE NEW EARLY IDENTIFICATION SYSTEM – YOUR NO WORRIES PACKAGE!

Availability, running costs and maintenance costs are considerable factors in the cost-effectiveness of gears.

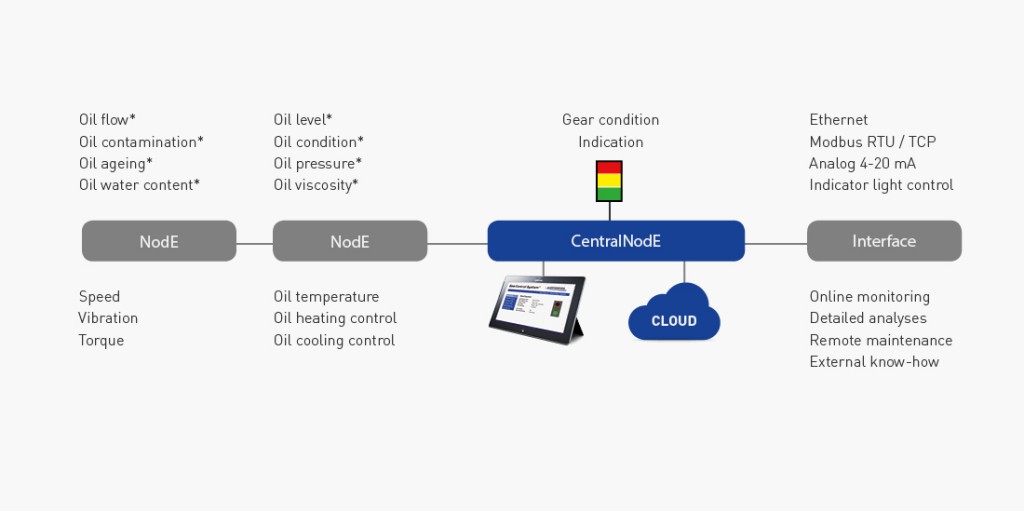

GearControl System records the condition of the gear throughout its entire service life from the testing phase at the manufacturer’s and during the whole period of operation and stoppage.

The measuring data gathered from this and information collected in combination with the models of the gear development are used to signal alarm statuses, prevent gear damage, optimise operating conditions and to determine condition-oriented maintenance, inspection and oil change intervals.

ADVANTAGES

- Early identification of problems and damage prevention

- Analysis and display of optimisation potential

- Clear action recommendations

- Top operational reliability

- Maximum reliability and availability

- Unbeatable cost-benefit ratio

- Gear and condition monitoring know-how

- Ready to use and easy to work with

- Remote maintenance and support

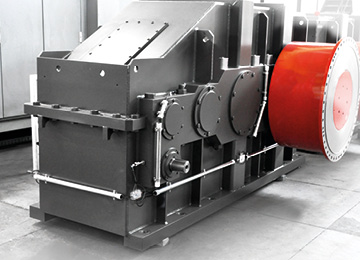

1) The i:GEAR 4.0® lifting gear with measuring sensors gives you the highest degree of efficiency in gear safety, diagnosis and control.

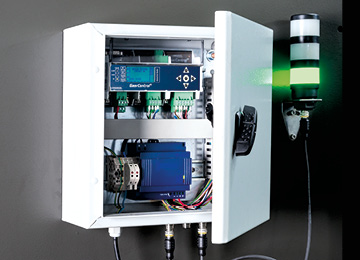

2) The Control-System CentralNodE control system. On the right: the indicator light system which gives clear visual signal on gear condition.

3) Various data links for control purposes are possible, including: online, offline, connection to central control unit or the engineering database.