STRIP PROCESSING

YOU CAN STRETCH IT AND LEVEL IT –

WHAT REMAINS IS QUALITY

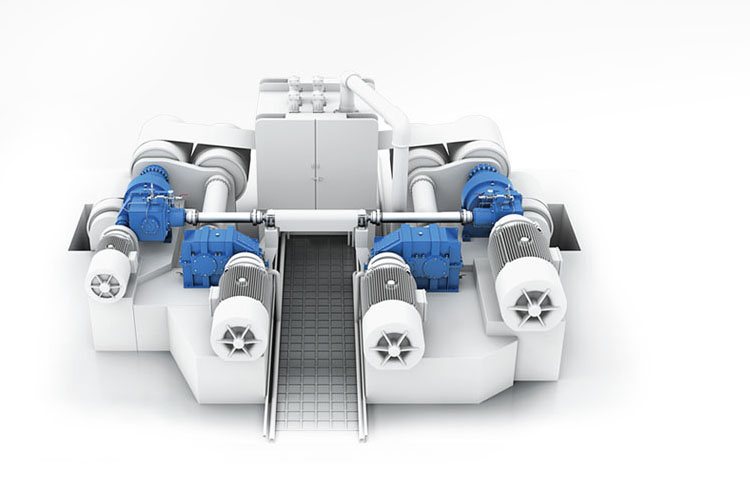

Half the motor power is required with electromechanical hybrid drives.

POWERFUL AND ENERGY EFFICIENT

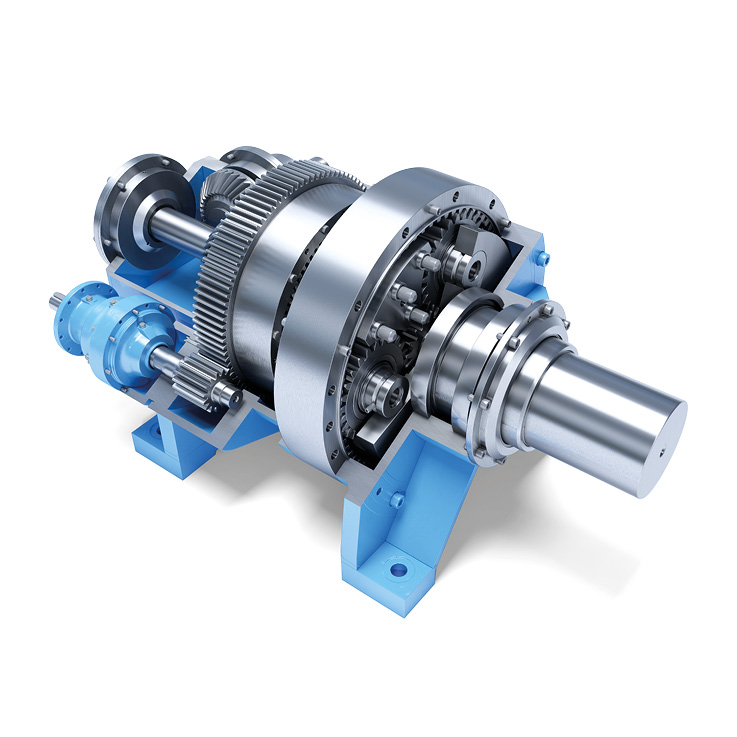

Thanks to our consistent specialisation in high performance gearbox building, Eisenbeiss continues to set standards in output and quality.

An ingenious gearbox lubrication system ensures the highest efficiency and leads to maximum safety in all operating conditions.

ENERGY EFFICIENT GEAR SYSTEMS

Bridle roll drives and accumulator winches

The patented Eisenbeiss energy saving concept achieves previously unattainable efficiency levels. This offers the following advantages:

- Low oil temperatures and a compact design

- External cooling fans are no longer needed

- Low losses reduce your operating costs

Use these advantages instead of wasting energy!

Levelling machines

High torques and low axle spacing with a bearing service life of 50,000 hours are required by modern levelling machines. Thanks to a power distribution solution developed especially for this application, Eisenbeiss achieves this effortlessly – even on machines with 17 rolls.

Strech leveler drive systems

Highest control precision – up to 20-tines higher than previously – in connection with low electricity consumption and low overall investment costs is delivered by Eisenbeiss hybrid drives for stretch levellers. With minimum space requirements, roll torques of up to 300 kNm and strip speeds of up to 500 m/min can be achieved with this innovative Eisenbeiss concept.

Coiler drives

If you are looking for smooth operation with switchable gear units then Eisenbeiss is the right partner for you.