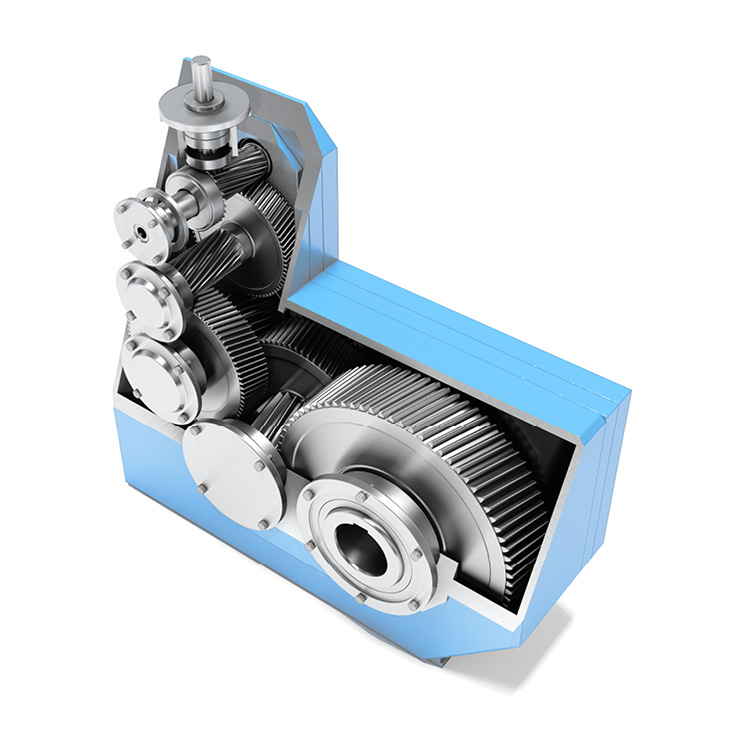

CONTINUOUS CASTING LINE GEARS

Thanks to integrated cooling and special seals, driver gears from Eisenbeiss are ideally suited to the extreme operating conditions in close proximity to a slab of glowing steel. For this harsh environment lubricant pumps have been developed that work without an external power supply and ensure that the gearing is lubricated reliably even in the case of extreme temperature differences.

In view of the very limited space available on continuous casting lines, the driver units are built with very compact dimensions. That is why the Eisenbeiss gear systems feature bevel gear stages; this makes it possible to set the motors at an angle of 90° to the driver rolls – aligned either vertically or horizontally.

TECHNICAL DATA

POWER RATING: 5 kW to 50 kW

OUTPUT SPEED: 2 to 15 rpm

RATIO: 100 to 750

LUBRICATION / COOLING: lubricated by own wedge lubrication pump / cooling optional via water-cooled gear casing

ADVANTAGE

![]()

APPLICATIONS

MOLTEN PHASE IN STEEL PRODUCTION

In the production of molten steel, plant availability and safety have the highest priority. We have the specific know-how in the development, fabrication and supply of special gear systems for cranes in the steel and aluminium industry.