PVC -EXTRUSION

BEING THE GLOBAL LEADER

CARRIES RESPONSIBILITIES,

WHICH IS WHY WE

DEVELOPED

TORQUE MASTER®

70%

INCREASE IN OUTPUT

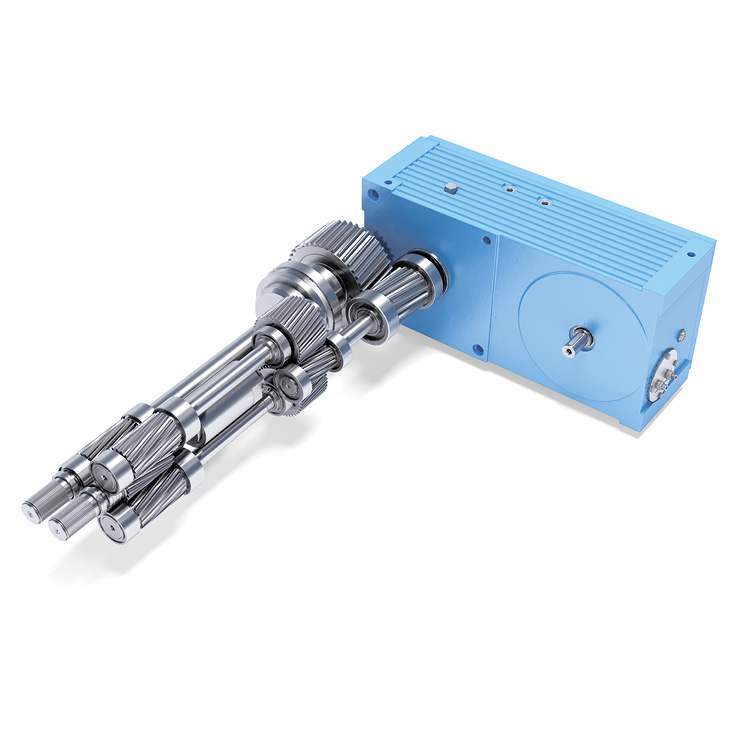

TORQUE MASTER® –

THE NEW DIMENSION IN PRODUCTION OUTPUT.

TPI (THE POWER INSIDE)

Eisenbeiss also manufactures other power distribution concepts

to meet specific requirements,

such as the 4-shaft gear system.

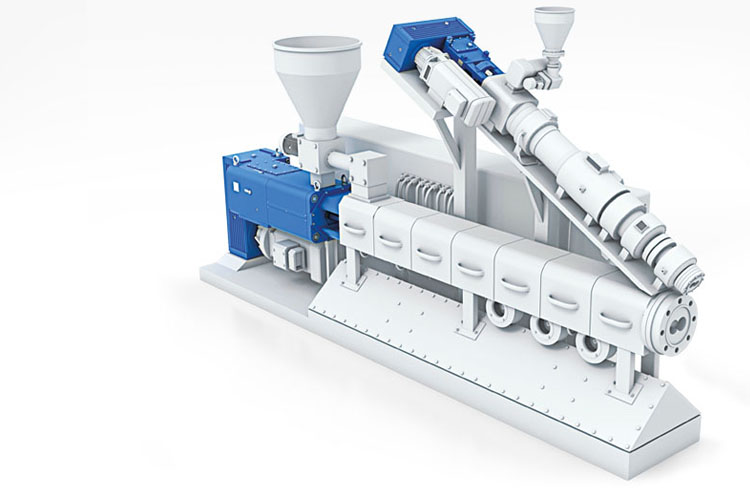

PVC-EXTRUSION

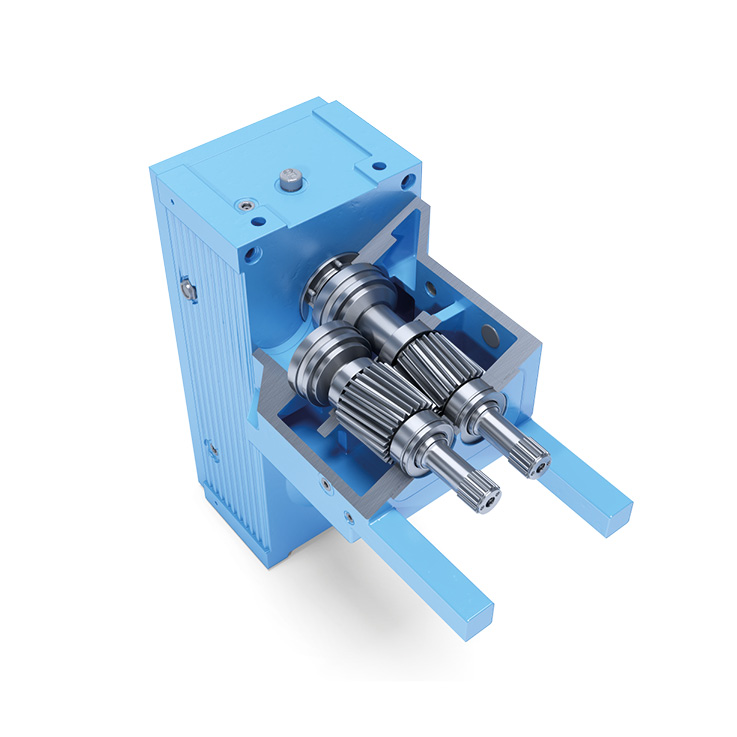

Parallel counter-rotating gear systems

The Torque Master® technology offers an increase in output of up to 70%. This means maximum production output and the longest service life. Resources are measurably saved by using 30% less material in the „Torque Master Direct Program“.

Our product range contains gear units for screw diameters between 70 and 175 mm.

Conical counter-rotating gear systems

With the case-hardened and grinded conical distribution stage, Eisenbeiss gear systems offer an increase in power of up to 30%. The gears deliver the highest possible reliability and safety. Leaks are prevented thanks to the innovative design of housing.

Our product range contains gear units for screw diameters between 35 and 125 mm.

GEAR SYSTEM SOLUTIONS

PARALLEL COUNTER-ROTATING GEAR SYSTEMS

The unique Torque Master® 4-shaft distributor system with intermeshing output shafts, has proven to be the most reliable and toughest solution in worldwide use, which is why the latest generation of counter-rotating gear systems – Torque Master Direct – is based on the same distribution principle.