GOIZPER – CAM GEARS

Emergency repair as a result of bearing damage

The Eisenbeiss Industrial Gear Service team in Sacramento / USA responded quickly and flexibly to a call out at Nor-Cal Beverages where bearing damage on a cam gear caused a beverage filling system to shut-down.

Due to the urgency of this case, an Eisenbeiss service truck was immediately dispatched to the customer to pick up the gear unit.

The gear unit was immediately dismantled, cleaned and inspected. All bearings and guides (cam rollers) as well as shaft seals were acquired locally and replaced.

Including final installation, test run and painting, the total turnaround time was 3 days when the renovated gear unit was delivered to the customer. Thanks to this rapid response, downtime at the customer’s plant was kept to a minimum.

Application: labelling system at a beverage filling plant

Gear manufacturer: Goizper

Type: unknown

Gear type: cam gear unit without continuous torque

Data for repair: no technical data available

Damage: bearing damage; shaft contacted bearing cap; gearbox blocked; leaks; corrosion

Work carried out:

- Immediate retrieval of bear unit from customer’s plant

- Dismantle, clean and assess gear unit

- Purchase and replace all bearings, including guide bearings (cams) and seals

- Installation, test run and painting

Turnaround time: 3 days

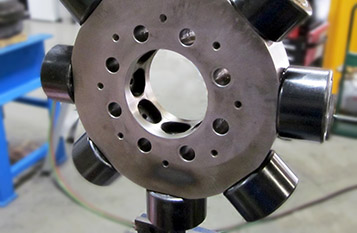

Dismantling cam gear; visible: drive spur gear, cam cylinder, cam roller star

Bearing damage to bearing on top of star

Damage to the star wheel bearing

Cam gear star

Gear unit ready for delivery to the customer

Repair Category:

More Examples