STRETCH LEVELLER DRIVE SYSTEMS

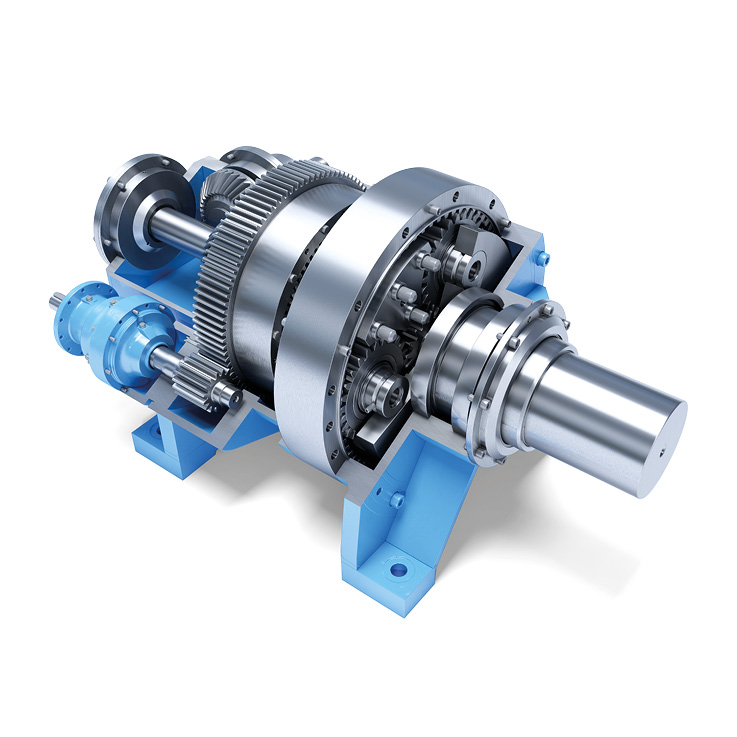

Eisenbeiss has developed a unique drive system for stretch levellers that features major advantages over conventional single-drive systems or hybrid-drive systems thanks to its purely mechanical linkage between planetary and override gear systems via a master shaft.

The entire system is driven by a single motor. Power is transmitted to all the rolls via a master shaft. The differing shaft speeds to stretch-level the sheet are achieved by coupling individually regulated drives that take advantage of the additional degree of freedom provided by the planetary system.

Because the planetary gearing has a very high gear ratio these regulating drives require relatively low power input. In addition, this configuration makes it possible to regulate the speeds of individual rolls with great precision so as to control elongation and compensate for variations in roll diameter.

With direct mechanical power delivery the mechanical power rating required goes down by more than 80% and efficiency is extremely high. This Eisenbeiss gearing solution not only reduces overall running costs considerably – as the main drive can be scaled down, less total investment is involved than with conventional systems.

TECHNICAL DATA

POWER RATING: main drive 200 kW to 1,000 kW

overdrive: 10 kW to 100 kW

OUTPUT SPEED: 20 to 160 rpm

RATIO: main motor: 4 to 200; overdrive: 100 to 1,000

LUBRICATION / COOLING: submerged lubrication with external cooler and central or decentralised oil pump

ADVANTAGE

![]()

APPLICATIONS

STRIP PROCESSING

Thanks to our consistent specialisation in high performance gearbox building, Eisenbeiss continues to set standards in output and quality. An ingenious gearbox lubrication system ensures the highest efficiency and leads to maximum safety in all operating conditions.