MOLTEN PHASE

IN STEEL PRODUCTION

SAFETY AND RELIABILITY

WITHOUT COMPROMISE!

In the production of molten steel, plant availability

and safety have the highest priority.

HUGE EXPORT SUCCESS THANKS TO DECADES OF EXPERIENCE AND

EXPERTISE

We have the specific know-how in the development, fabrication and supply of special gear systems for cranes in the steel and aluminium industry. TATA STEEL, the world’s fifth largest steel producer, decided at the end of 2010 to use Eisenbeiss hoist gear systems for the 500 t casting cranes at their new steelworks in Orissa. A major export success for Eisenbeiss.

MOLTEN PHASE IN STEEL PRODUCTION

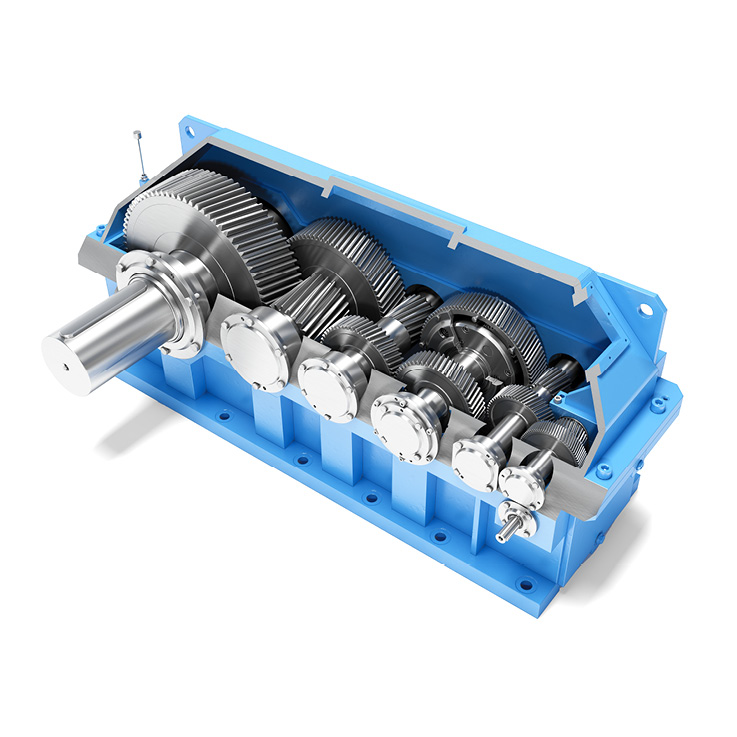

Gear systems for steelworks

Lance winches, crucible tilters and casting cranes are our specialities. Thanks to our decades of experience with these gear systems, we deliver robust, low maintenance special gear systems with no compromises on safety and quality.

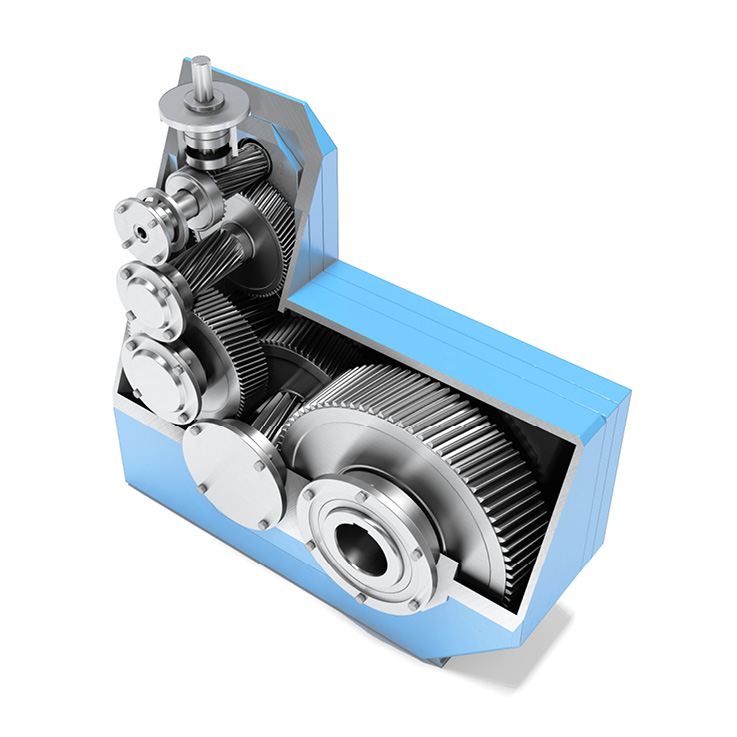

Gear systems for continuous casting – ladle turret gear systems

offer safety during power failure with emergency operation and protection against extreme forces up to 4-times the nominal load to account for impacts if the ladle is not handled with precision.

Section drivers

are especially geared for rough conditions. Equipped with the right sealing and cooling systems to cope with these requirements, these units are ready to face the most extreme conditions. The narrow series also enables small distances between each support.

Cranes

We have the specific know-how in the development, fabrication and supply of special gear systems for cranes in the steel and aluminium industry.