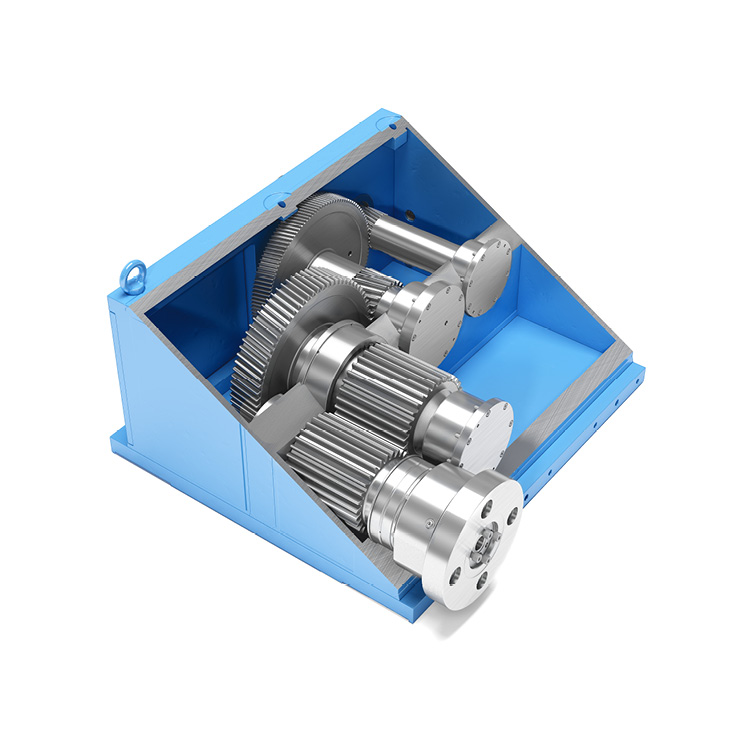

GEAR SYSTEMS FOR CIRCULAR SAWS

The special characteristics of this field of application are the impact stresses that need to be absorbed during the sawing process. The situation is especially critical at the beginning and end of the process, when only a few saw teeth are in contact with the material.

To keep the gear system running smoothly in spite of these irregular loads, it is essential to minimize the amount of play between the gears and to cushion the shocks impacting the unit. Here it is very important to dimension gears and bearings with extreme precision, and to design the gear system housing appropriately.

Spur gear systems in the Eisenbeiss gear series developed for this application are available in two-stage or three-stage designs.

TECHNICAL DATA

SERIES: DX or GDX

POWER RATING: 100 to 500 kW

RATIO: 8 to 64

LUBRICATION / COOLING: submerged lubrication with natural convection

POWER RATING: 100 to 500 kW

RATIO: 8 to 64

LUBRICATION / COOLING: submerged lubrication with natural convection