HYDROPOWER

FIT AND FORGET

EISENBEISS DELIVERS THE RIGHT GEAR SYSTEM SO THAT THE POWER OF THE WATER ISN’T A LOAD OF HOT AIR.

Our gear systems deliver the highest efficiency thanks to optimised meshing

and bearings. They also have a low maintenance requirement thanks to our in-house developed

Condition Monitoring Sensors. This all leads to higher output and earnings.

The gear systems are well-known for their low noise level and they minimise the

impact on people and natural surroundings. Regardless of whether it is for pit, bulb or

Kaplan turbines, Eisenbeiss has the better solution.

EISENBEISS IS THE SPECIALIST FOR LOW PRESSURE TURBINES.

The series designed by Eisenbeiss especially for low pressure turbines meets all requirements in terms of space requirements, installation and optimised gear ratios. Naturally, this series also takes into account all the common hydropower malfunction scenarios such as short circuit, power failure and emergency stops.

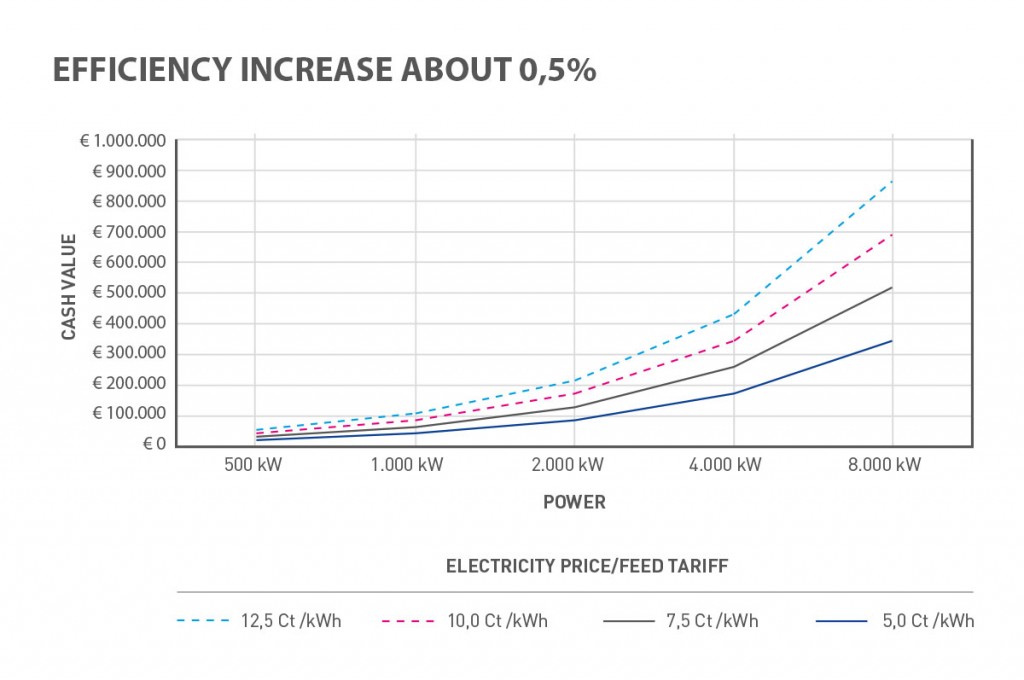

Compared to other products and solutions, Eisenbeiss gear systems deliver higher profits because they deliver the highest efficiency.

GEAR SYSTEM SOLUTIONS

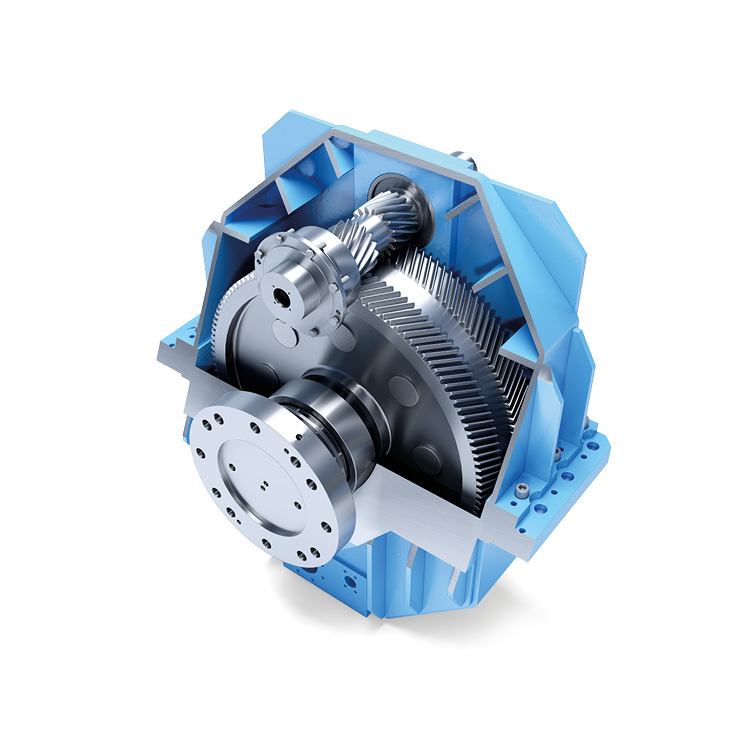

SPUR GEAR SYSTEM FOR PIT TURBINES

Developed specifically for pit turbines, these gears are of robust, compact design and are around 99% efficient. They feature double helical gearing optimized for this particular application, anti-friction bearings and perfectly-matched oil lubrication.

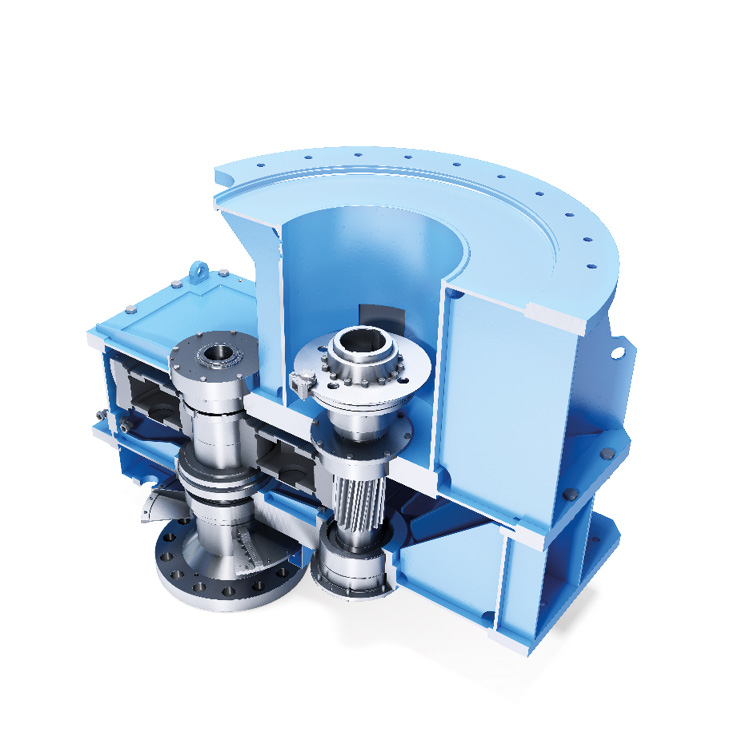

VERTICAL SPUR GEAR SYSTEMS FOR KAPLAN OPEN-FLUME TURBINES

This gearing design is fully adapted to the tough requirements applying to a vertical water turbine. For example, the turbine shaft is hollow-bored so that the rotor blades can be adjusted from above using the gear system. The generator bell is a solid design with fins and is welded directly to the housing.

HELICAL BEVEL GEAR SYSTEMS

Hydroelectric power stations are often inside listed buildings. The structure of these buildings cannot be altered. If such a power station with open-flume turbines needs to be modernized, it is essential to adapt to the circumstances on site; in particular, the way the generator is situated determines which gear system design is required.

BEVEL GEAR SYSTEMS

The heart of an Eisenbeiss bevel gear system for bulb-type turbines is a bevel gear hard milled in a special process which ensures the very highest surface quality of the gear teeth. In conjunction with a housing designed for strength, this guarantees low levels of noise and vibration.