GEAR SYSTEMS FOR ABRASIVE CUTTING MACHINES

The operating conditions for abrasive cutting machine gears are extreme heat combined with excessive dust. In addition, the pressure applied to the cutting disc during abrasive cutting must be reliably accommodated by the gearbox casing without the casing or the drive shaft deforming in any way. The very high output speeds required for the abrasive cutting process (up to 4,000 rpm) places high requirements on the gear system bearings. To meet these requirements, Eisenbeiss has developed a gear concept that has already proven its reliability in a wide range of industrial applications.

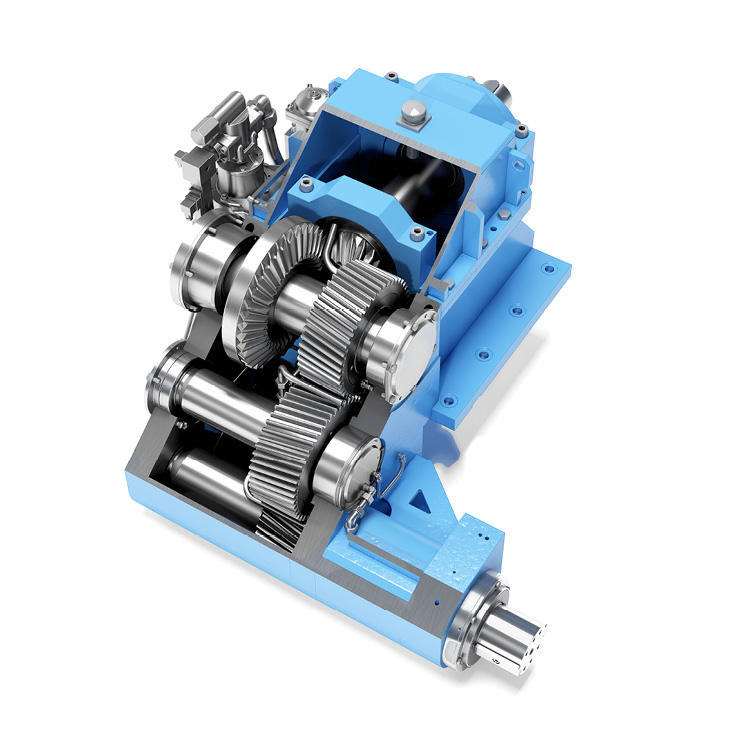

Because the normal configuration of abrasive cutting machines places the motor and gear unit in parallel to the cutting disc, the Eisenbeiss gear concept features a bevel gear stage at the gearbox intake.

To create the cutting movement during the abrasive cutting process, the gearbox is slowly tilted causing the oil level inside the gear unit to fluctuate. An external oil lubrication unit with integrated cooling ensures that sufficient oil is supplied to the gear teeth and bearings at the correct temperature regardless of the angle of the gear unit.

TECHNICAL DATA

SERIES: KGX

POWER RATING: 100 to 600 kW

RATIOS: 0,5 bis 2

LUBRICATION / COOLING: external forced-feed lubrication with air or water cooling