COMPOUNDING

CO ROTATING

SPEED STAR®

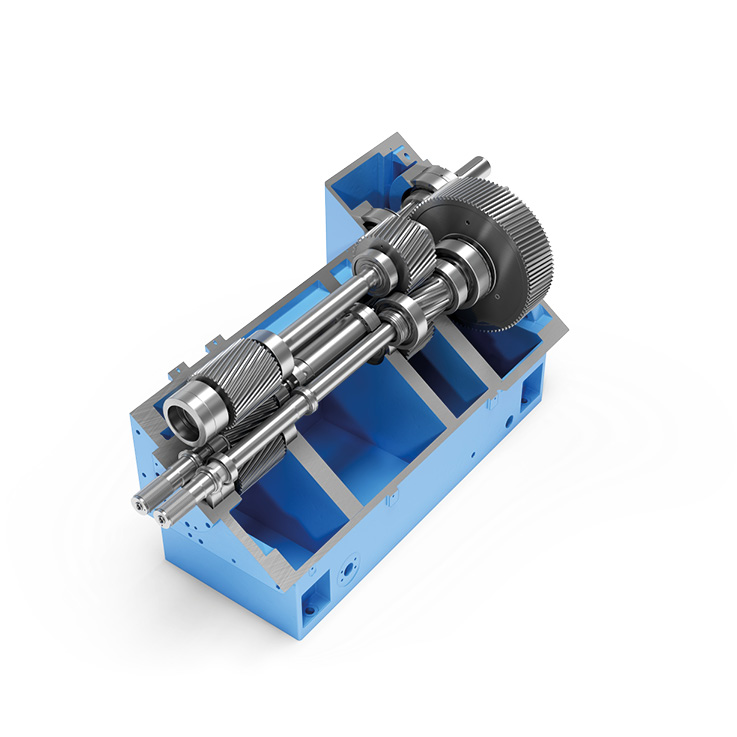

The Speed Star® twin screw extruder gearbox sets new standards in production output with the highest torque, high cost effectiveness and long service life.

COMPOUNDING

The Speed Star concept is unique

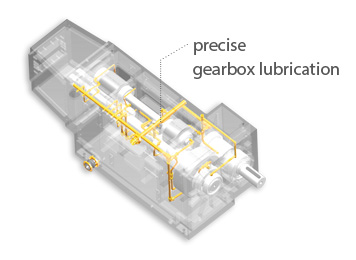

Torques of up to 20 Nm/cm³ per shaft are possible at operating speeds of up to 1800 rpm. This provides our customers with a much higher production output. The gear unit consists of a single-piece housing without any joins, completely eliminating potential leaks. The special configuration of the distribution shafts means we can make our gear units more compact and save on resources. On top of the gearbox there is a large inspection cover which is ideal for inspecting the gears.

High efficiency is enabled thanks to defined oil flowrates per tooth intermesh and bearing. To meet a wide range of export market requirements, these gear units are used, for example, in the manufacture of raw materials for injection moulding machines and powder paint or master batch production.

Our Speed Star® twin screw extruder gear units are also available as ATEX compatible versions and nickel-plated versions for the pharmaceutical industry.

The product range includes gear units for screw diameters between 25 and 240 mm.