EISENBEISS – TURBINE GEAR UNIT FOR SMALL HYDROELECTRIC POWER STATION

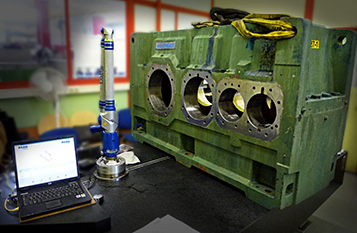

Corrosion damage as a result of incorrect storage

Application: turbine gear unit for small hydroelectric power station

Gear manufacturer: Eisenbeiss

Type: TGVF 1015

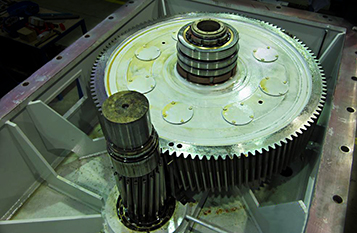

Gear type: spur gear system

Data for repair: drawings and parts list available

Damage: bearings and gear teeth heavily corroded as a result of incorrect storage

Work carried out:

- Dismantle and install gear unit

- Re-grind pinion shaft and spur gears

- Purchase and replace all bearings and seals

- Check all fitted components

Turnaround time: 3 units within 4 weeks

Delivery condition of the 3 gear units

Plan view after dismantling the spur gear stage with axle spacing 1015 mm

Severe corrosion of bearings and gear tooth surfaces on pinion

Repair Category:

More Examples