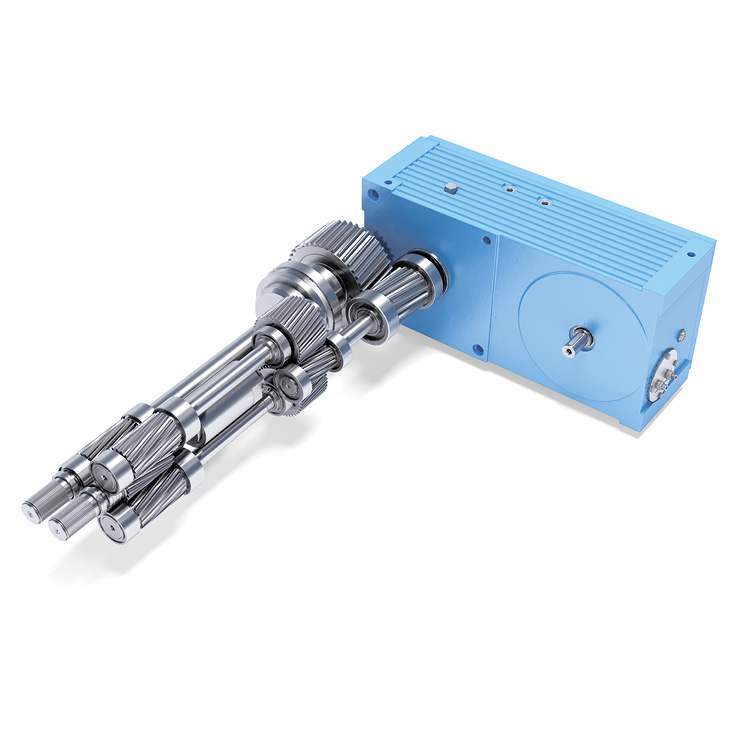

PARALLEL COUNTER-ROTATING GEAR SYSTEMS

In response to the steady trend toward higher and higher outputs from extrusion facilities, the unique Torque Master® 4-shaft distributor system with intermeshing output shafts, has proven to be the most reliable and toughest solution in worldwide use, which is why the latest generation of counter-rotating gear systems – Torque Master Direct – is based on the same distribution principle.

Consistent focus on energy-efficient operation and a compact, straightforward design once again make the new Torque Master Direct gear system the benchmark in the field of PVC extrusion with its very low operating costs and excellent price/performance ratio.

Eisenbeiss parallel counter-rotating gear units are designed precisely to meet each customer’s specifications.

TECHNICAL DATA

OUTPUT TORQUE: 4,000 to 65,000 Nm per shaft

OUTPUT SPEED: 20 to 50 rpm

RATIO: 35 to 100

LUBRICATION / COOLING:

combined splash and forced-feed lubrication with optional oil cooling

SCREW BACK PRESSURE: up to 500 bar constant load

SCREW DIAMETER: 70 to 175 mm

ADVANTAGE

![]()

![]()

APPLICATIONS

PVC-EXTRUSION

Thanks to consistent specialisation Eisenbeiss have become a dynamic, innovative and internationally leading centre of competence for drive concepts in the field of plastics extrusion. The leading machinery manufacturers in the extrusion branch count on the expertise of our engineers and also our many years of experience in producing special gear systems.