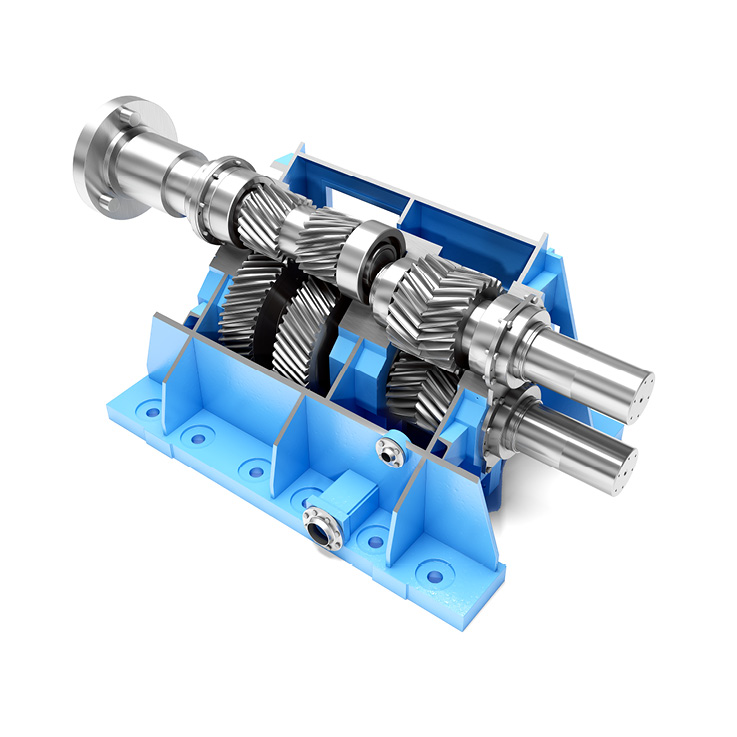

SINGLE-DRIVE GEARS

Eisenbeiss single-drive gears stand out through their compact horizontal or vertical designs. The high power density of the double helical gearing enables the transmission of up to 6 MW with pinion distances of only 400 mm in parts. The use of open-die forging shafts means that no shaft/hub collar connection is required in the gear unit. No feather key can be squashed and no gear shaft connection can be damaged even in the event of the strip tearing.

Because Eisenbeiss always uses proprietary brand bearings with solid cages we are able to supply long-lasting, robust stand drives for tandem mills or reversing mills up to a service life of 100,000 hours.

TECHNICAL DATA

POWER RATING: 100 kW to 6,000 kW

RATIO: 1 to 16

LUBRICATION / COOLING: forced-feed lubrication / external cooling

ADVANTAGE

![]()

APPLICATIONS

ROLLING MILLS

Eisenbeiss has developed special gear systems for cold rolling mills that enable closer axle spacing to achieve small roll diameters. Thanks to the high power density of the gears it is possible to process high tensile steel and aluminium products. The gears are designed for smooth and vibration free operation, which is especially important when processing thin aluminium sheet.