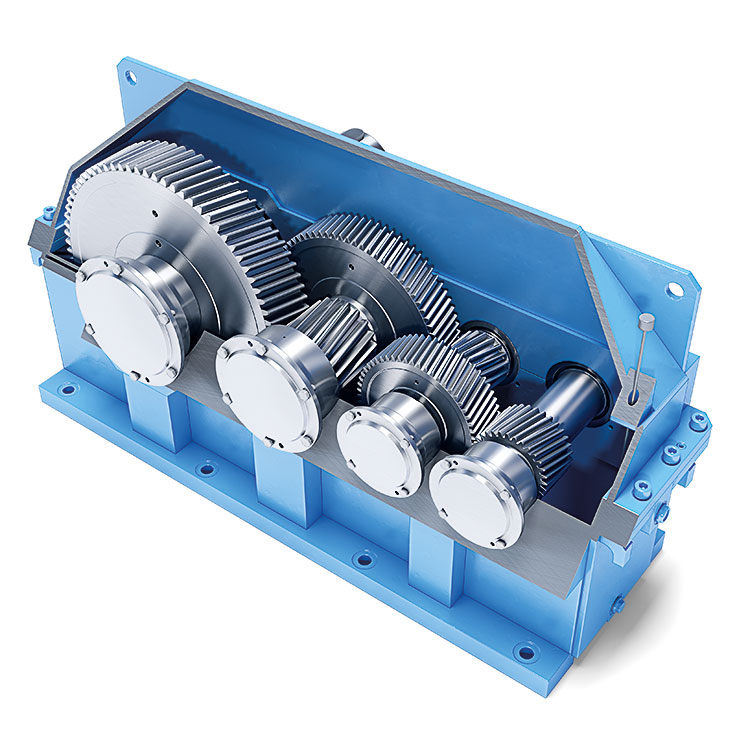

BRIDLE ROLL DRIVE

Thanks to optimised toothing, bearing assembly and lubrication, power loss with this application is reduced by about 30% compared to conventional solutions. Not only are energy costs reduced as a result but in almost all cases no additional cooling is required. This in turn reduces service work to an absolute minimum. The gearboxes remain straightforward and stable in operation. Combined with the built-in quality brand bearings, this gives our customers a high level of plant availability.

TECHNICAL DATA

POWER RATING: 20 kW to 800 kW

OUTPUT TORQUE: 20 to 300 rpm

RATIO: 90 to 350

LUBRICATION / COOLING: submerged lubrication and cooling via gear casing

OUTPUT TORQUE: 20 to 300 rpm

RATIO: 90 to 350

LUBRICATION / COOLING: submerged lubrication and cooling via gear casing

ADVANTAGE

![]()

No additional cooling is required thanks to the excellent efficiency of these gear units. As a result no fan is required, eliminating the risk of dust being drawn in.

APPLICATION

STRIP PROCESSING

Thanks to our consistent specialisation in high performance gearbox building, Eisenbeiss continues to set standards in output and quality.