FLENDER – SPUR GEAR SYSTEM

Tooth break repair with re-engineering

Application: paint mixing plant

Gear manufacturer: Flender

Type: H3 SH 17

Gear type: spur gear system

Data for repair: no technical data available

Damage: teeth worn on pinion shaft; self-aligning roller bearing worn

Work carried out:

- Make new pinion shaft

- Replace complete bearing assembly with shaft seal

- Grind the gear teeth

- Final calculation using Rikor (cause analysis, correction grind)

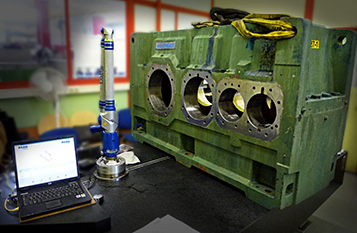

- Measuring gear unit casing (check axle position)

Turnaround time: 4 weeks

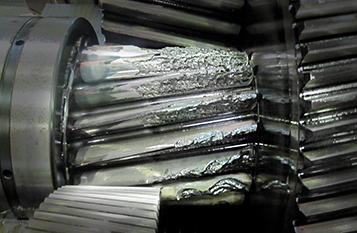

Gear condition before and after repair

Clearly visible damage to pinion teeth on 3rd spur stage

Casing measured during quality control.

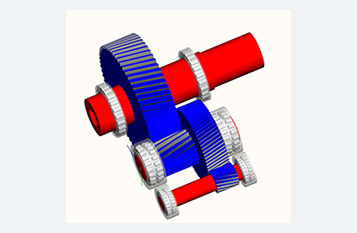

Recording sample using gear tooth measuring machine

Final calculation and optimization of correction grind

Assembly with newly made and precision-ground gear parts

More Examples