ROLLING MILLS

PLANT AVAILABILITY

AROUND THE CLOCK

EISENBEISS OFFERS SPECIAL GEAR SYSTEMS THAT INCREASE PERCENTAGE OUTPUT BY DOUBLE FIGURES THANKS TO A HIGH POWER DENSITY WITH THE SAME SPACE REQUIREMENT.

Only plant planning knowledge can guarantee safety where

it is needed and is essential. That is the only way to avoid unnecessary over-engineering.

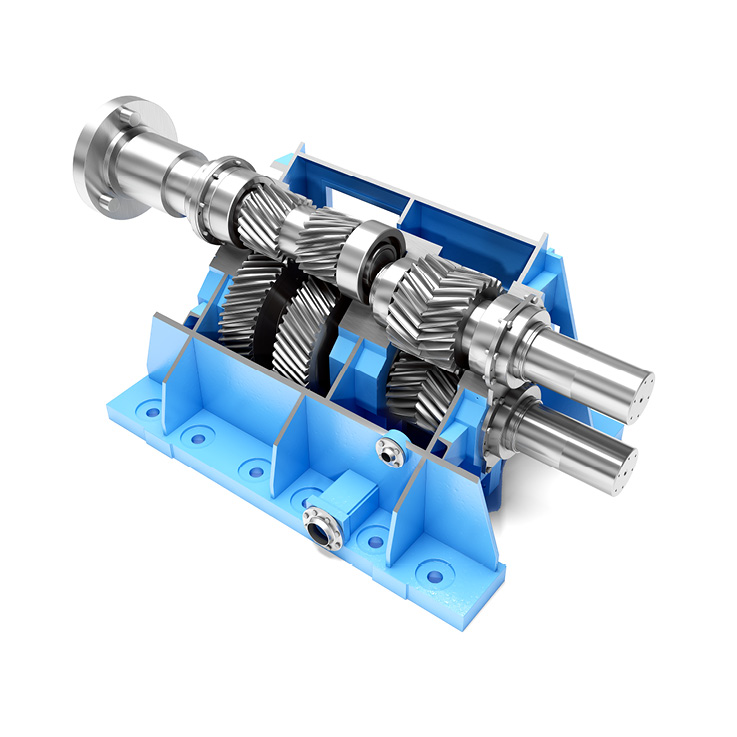

HIGH POWER DENSITY

SHORT AXLE SPACING

QUALITY THAT PAYS FOR ITSELF!

Eisenbeiss has developed special gear systems for cold rolling mills that enable small axle spacing to achieve small roll diameters. Thanks to the high power density of the gears it is possible to process high tensile steel and aluminium products. The gears are designed for smooth and vibration free operation, which is especially important when processing thin aluminium sheet.

ROLLING MILLS

Gear systems for transporting slabs

Ingot pushers, slab upenders, transport systems — Eisenbeiss offers gear systems especially designed for these applications that have cost advantages over standard types of gear unit that are normally over-dimensioned.

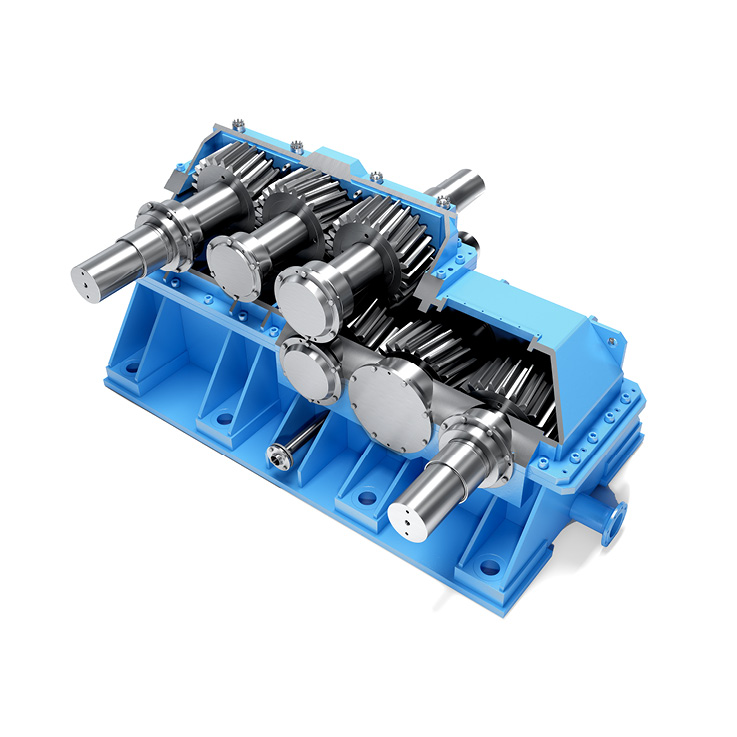

Gear systems for hot rolling mills

For long products, Eisenbeiss offers the full range of gear systems from the entry mill to the finishing mill. Eisenbeiss pinion gears in horizontal or vertical configurations have been designed to operate in extremely tough environments involving mill scale, dust and cooling water.

Gear systems for cold rolling mills

The surface finish of cold-rolled sheet is the most important quality criterion of the cold rolling process. To achieve a perfect surface finish you need to eliminate vibrations as far as possible from the whole drive system. Eisenbeiss applies highly advanced methods to reduce drive oscillation.

Gear systems for wire rolling mills

At high-speed wire rolling plants – with wire travelling at up to 120 m/sec – the highest quality gear systems ensure smooth operation and a bearing service life of up to 80,000 hours. Special seals protect input and output drive shafts against dirt and scale and prevent cooling water ingress as well as oil leaks.